Which maintenance schedule is right for me?

The ability to predict equipment failure is sought after by businesses where unscheduled downtime equals a loss of profit. If your maintenance schedule is not currently working for you; or resulting in lost equipment, unscheduled downtime, or high repair costs; then you may need to think about another way to take care of your equipment. Throughout this article we will look at four different maintenance schedules and the pros and cons of each, to help you choose the right schedule for your application.

Run to Fail (RTF)

Cost: $18/hp/year*

Run to fail is a popular maintenance schedule, since it requires the least amount of upfront costs, and the least amount of labor. Basically, with this method you will only fix things when they break. While this is okay for low cost/low importance equipment, it is unacceptable for critical equipment.

Pros:

- Little planning involved

- Ideal for low priority/inexpensive equipment

- No upfront cost

- Less staff needed to maintain equipment

Cons:

- Can cause maintenance backlog when things go wrong

- Can cause excessive downtime

- High cost associated with parts and labor when equipment fails

- Possible secondary equipment damage from equipment failure

- Inefficient use of staff resources

Preventative Maintenance (PM)

Cost: $13/hp/year*

The primary goal of Preventative Maintenance is to assess your motor’s health through electrical tests, mechanical assessments and physical examinations. Electrical tests will measure individual phase voltage, currents, and insulation resistance. Mechanical tests measure vibration through FFT and checking alignment. Other preventative measures include cleaning, adjusting belt tension, increasing bolt tightness, and acoustical analysis.

Pros:

- Extends life of assets

- Fewer unexpected breakdowns

- Audits are easily passed

- When used with an MCCS, asset knowledge and work history is recorded centrally

- Less expensive corrective repairs

- Less downtime

- Cost effective

- Flexibility allows for adjustment of maintenance scheduling

Cons:

- Maintenance creep can occur if you don’t stay on schedule

- Post-maintenance breakdowns can occur when tasks are not completed correctly

- Labor intensive

- Includes performance of possibly unneeded maintenance

Predictive Maintenance (PdM)

Cost: $9/hp/year*

A predictive maintenance schedule focuses on when to perform maintenance to reduce chance of failure and/or when to perform maintenance to prevent a failure. Using sensors to complete a myriad of tests in real time, and then comparing them to baseline readings to find worrying trends in vibration, acoustics, and infrared analysis is the main idea of predictive maintenance. According to a study done by the Department of Energy, predictive maintenance eliminates 75% of equipment breakdowns.

Pros:

- Uptime is optimized as maintenance occurs only when necessary

- Decision making is data-driven and condition based

- Increased operational life of equipment

- Decrease in parts and labor cost

- Improved worker and environmental safety

Cons:

- High cost associated with implementation

- Advanced approach that requires analysis and a specific skill set

- Savings potential is not readily seen at first

Reliability Based Maintenance (RBM)

Cost: $6/hp/year*

Reliability based maintenance is a combination of reactive maintenance (also known as Run to Fail maintenance), preventive maintenance activities, and predictive maintenance analysis. RBM states that the motor will perform a certain way for a specific amount of time with no intervention. This reduces maintenance to the most cost effective activities which require a technician with an understanding of the signs of motor failure to create the maintenance schedule for each individual piece of equipment.

Pros:

- Reliability is maximized as each piece of equipment gets its own maintenance plan

- Maintenance is prioritized according to equipment criticality, which reduces risk

- Can be the most efficient program when done correctly

- Lowers cost by eliminating unnecessary maintenance or overhauls

- Reduced probability of sudden equipment failures

- Ability to focus maintenance activities on critical components

- Incorporates root cause analysis

Cons:

- Requires a large investment of time and money

- Many teams don’t have the resources to adopt this approach

- Cost saving potential is not readily seen by management

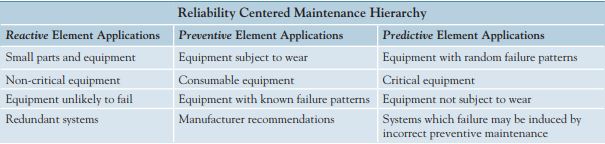

The Department of Energy released a helpful table to help you decide what type of maintenance should be done on which types of equipment for a reliability based maintenance schedule.

*These figures were taken from an article entitled “Pro-Active Maintenance for Pumps” by Piotrowski, J. April 2, 2001. You can find this article at http://www.pump-zone.com

While reliability based maintenance is the best schedule for most applications, taking into account your manpower, budget, and equipment will help you find the best maintenance schedule for you.

This article is based on our EMC Webinar: Getting the Most from Your Electric Motor

Got More Motor Questions? We Can Help!

Call 800-595-5315 Or Connect With Our Expert Technicians Here:

Other Articles

- How to Reduce Motor Downtime and Keep Your Motor Happy

- Critical Spare Planning

- The Three Most Common Externally Caused Motor Failures

Craig is the Vice President of Engineering at Energy Management Corporation. He is a Professional Engineer (PE) and carries over 30 years of experience in the world of electrical automation. Besides amassing an impressive amount of knowledge in his magnificent brain, he is also a Master Scuba Diver (MSD), a performing magician, and a professional DJ. Truly a man of many talents.