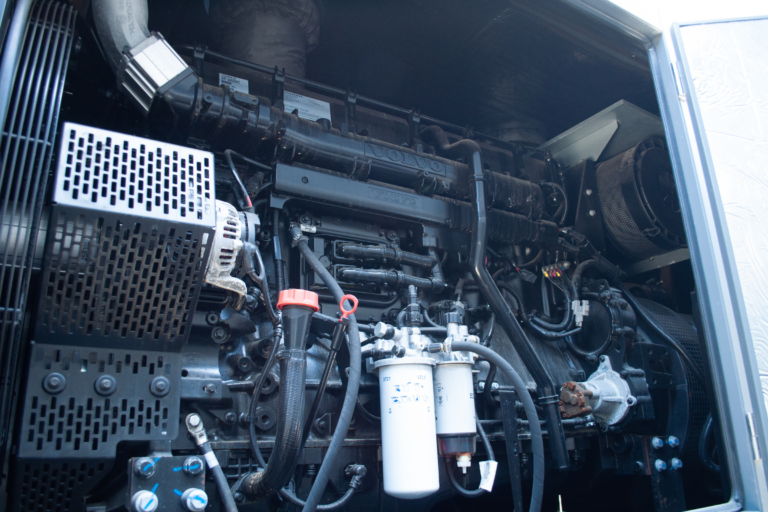

Why your Standby Generator should have regular oil changes

Regular oil changes are a necessity for any engine, but they are especially important for the engines you rely on in the case of an emergency. If you are not performing regular oil changes on your generator, you are asking for it not to start the next time you need it. In this article, we will address why oil is so important to your engine, what causes oil contamination, and how often you should be changing your oil for the best results.

Why is Clean Oil Important?

Your engine uses oil for a myriad of different reasons. Oil is used to seal piston rings to reduce leakage and prevent any external contaminants from entering. It is also anti-rust and anti-corrosion. It increases lubrication, reduces wear; and it keeps things clean by bringing back carbides, sludge, and wear particles from the working surfaces back to the oil tank. It helps cool the engine by bringing heat back to the oil tank and dissipating it into the air and it is also a great buffer and shock absorber.

Clean oil also improves horsepower performance, reduces friction and impurities in your engine; and prevents overheating, engine part failure, grinding parts, fusing of parts or jamming.

What Can Cause Oil Contamination?

- Oil can become contaminated for a myriad of reasons. The most common contaminants are combustion by-products; such as exhaust gases that contain carbon, water, acids, partially burned fuel, varnish, and lacquers.

- Acid, varnish, and sludge can be produced by oil coming into contact with very hot engine components and immediately oxidizing and decomposing creating these contaminants.

- Fuel is only found in oil if there is an engine malfunction.

- Water can enter the oil as a byproduct of combustion. Generators that run at low or no load don’t allow the oil to get hot enough to boil off the excess water quickly enough.

- Coolant could be present in oil due to cooling system corrosion, head gasket seal rupture, or improper coolant line fittings.

- Soot in your oil can come from retarded injection timing and burning fuel mixed with oil on the cylinder liners.

When Should I Change my Oil?

The best way to go about this is to look at your generator manufacturers recommendations. Most warranties are voided if you do not perform the regular maintenance recommended by your manufacturer.

There are also fairly inexpensive oil status indicator tools available on the market today. There are versions that are more expensive and require more technical knowledge to use, but they are not readily available to laypeople. Most oil analysis tools only use a couple drops of your engines oil to perform their analysis and will give you an almost immediate recommendation as to whether you should change your oil at that time, or if you have some leeway.

You can also do a few quick at home tests that don’t require any special equipment to give you a general idea if your oil is too contaminated.

- Oil Flow Observation: Put a good amount of oil from your generator into a cup. Pour that oil into another cup and observe. Clean oil should pour slender, uniform and continuous. If you notice non-uniformity in color, thickness, or width of pour, you should probably replace your oil.

- Illumination: Get a few droplets of oil onto a hard surface. Illuminate these drops from the back and observe the droplets for wear debris. This will show up as small black flecks suspended in the oil or a slight darkening of the overall color of the oil.

- Oil Drop Trace: Put a drop or two of oil onto a white paper towel; leave the oil to absorb for a few moments. Once all oil is absorbed, observe the paper towel. There should be no black marks or powder left on the towel. It should look clean, dry, and a little yellow.

- Hand Twist: Dip your finger into the oil, then rub the oil repeatedly between your thumb and pointer finger. You should not be able to feel any grittiness or see any black specks in the oil.

Quick Tips

To keep your engine oil in tip top shape between changes:

- The first oil change after initial installation comes quicker than the rest. It could be as early as 8 running hours after initial install. Refer to your owner’s manual for specific guidelines.

- Check oil levels weekly. Top off as needed.

- Top off the oil reservoir if necessary whenever you refuel.

- Follow manufacturer guidelines when it comes to type of oil you should use for your equipment.

- Consider the ambient temperature of your equipment when creating an oil change schedule and deciding which type of oil to use in your generator.

- Also take into account the area your generator is installed in, if it is dirty, you will need oil changes more frequently.

- Change out the oil filter whenever you change the oil.

Got More Generator Questions? We Can Help!

Call 800-595-5315 Or Connect With Our Expert Technicians Here:

Other Articles

- Critical Spare Planning

- Where Do I Start On My Generator Installation?

- How can Las Vegas heat lead to generator failures?

Craig is the Vice President of Engineering at Energy Management Corporation. He is a Professional Engineer (PE) and carries over 30 years of experience in the world of electrical automation. Besides amassing an impressive amount of knowledge in his magnificent brain, he is also a Master Scuba Diver (MSD), a performing magician, and a professional DJ. Truly a man of many talents.