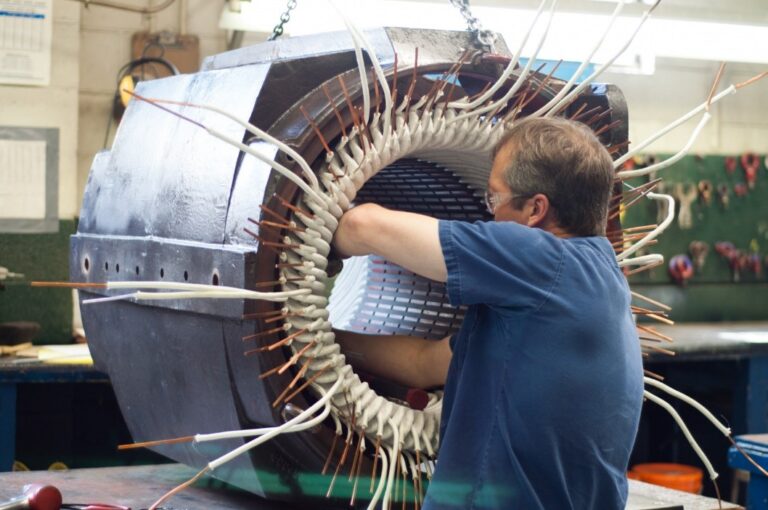

What you should look for in a quality motor shop

A quality motor is a large and expensive purchase. If something goes wrong, you want to make sure that you choose a repair shop that does quality work for a fair price. This article will cover some of the most important things you should look for in your future repair shop.

Quality Motor Inspection & Repair

Your motor repair shop should do a wide variety of tests to ensure that your motor is running the way it is supposed to.

Some of the most critical things your shop should be able to do are:

- Balance the rotors.

- Check for open rotor bars.

- “Mic” the bearing fits.

- Surge test the motor.

- Complete a core loss test and report.

- Cut the bearing races to inspect for fluting or other damage.

- Fully test the motor after repair.

- Do a full tear down and inspection report (large motors only).

- Use green motor practices to preserve and enhance motor efficiency (Be a certified facility).

- Perform all motor repairs in accordance with EASA best practices (Be an accredited facility).

- Use best practices on bearing selection and installation (Be a certified facility for your type of bearing).

EASA Accreditation

Electrical Apparatus Service Association, Inc. (EASA) accreditation is a lot harder to obtain than a simple EASA membership. Accreditation requires strict compliance with EASA’s most stringent standards, including calibration, training, and best practices per EASA AR100. It regularly requires third-party audits of the shop, tools, shipping, and ordering procedures. Energy Management Corporation was the second EASA accredited facility in the United States. Ask your motor shop to see their EASA accreditation certificate. If they can’t show it to you, find another shop!

Green Motors Certification

This certification certifies that the rewind facility follows best practices in preserving motor efficiency, including pre and post wind core tests insuring that core losses are less than 6 watts/lb. Windings must also be tested for maximum efficiency. Green motors certification of your motor is often required for rebates from utilities such as Rocky Mountain Power.

UL Certification

This certification is required for explosion proof motors or any motors used in a hazardous location. In order for a shop to be able to give a motor a UL certification, it must pass a rigorous 51 point inspection. Technicians must go through a special training to be able to give out these important certifications.

Bearing Manufacturer Certification

Bearing manufacturers offer their own certifications; assuring that your rewind facility employees follow best practices in bearing inspection, handling, installation, and testing. Certifications require manufacturer training and regular facility audits.

If your motor shop can’t prove to you that they have the proper certifications or do a thorough and meticulous job, come visit us at Energy Management. We make sure that each motor that passes through our shop doors is thoroughly inspected, repaired, and returned with the utmost care.

The information for this article came our EMC Webinar: Getting the Most Out of Your Electric Motor

Got More Motor Questions? We Can Help!

Call 800-595-5315 Or Connect With Our Expert Technicians Here:

Other Articles

- How to Reduce Motor Downtime and Keep Your Motor Happy

- Critical Spare Planning

- The Three Most Common Externally Caused Motor Failures