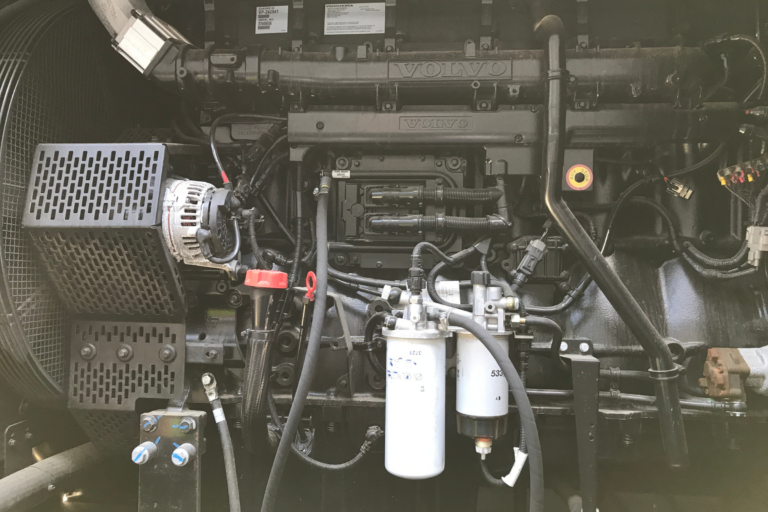

Don’t wet stack your Diesel Generator

In the world of diesel engines, wet stacking is extremely common. If you are not running your engine at recommended operating temperatures one hundred percent of the time, you are bound to have some level of wet stacking occur. Diesel generators usually run at suboptimal temperatures when they don’t have at least a 60% load while in use; this means the engine never reaches the temperature level needed to burn off the excess fuel and carbon deposits, which leads to build-up in the exhaust system known as “wet stacking”.

How Do I Know It’s Happening?

The first indicators of wet stacking are usually black ooze around the exhaust pipe or continuous black exhaust smoke. You can assume that your generator is wet stacking if you operate your generator under the recommended operating temperature, run your generator with less than a 60% load, use the incorrect air-to-fuel ratio, allow your generator to go unused for long periods of time, or run the engine with too much or too little fuel in the tank.

How Can I Prevent It?

To prevent wet stacking, regularly exercise your generator according to NFPA and manufacturer guidelines (at least once a week with at least a 60% load), always run your engine at optimal temperatures, make sure the fuel tank is always full, have a qualified technician maintain your generator at regular intervals, and make sure that the internal temperature of your generator reaches manufacturer recommendations if you’re operating in cold conditions.

If you begin to notice a buildup of fuel and soot particles, sometimes the answer is as simple as running your engine at optimal levels for a few hours to burn them off. Higher levels of particulates may require a load bank to simulate a full load for your generator and a qualified technician to perform this load banking procedure.

What Happens if I Don’t Address it?

If you do not address wet stacking at regular maintenance intervals, unburned fuel will begin to build up in your exhaust system. This can clog your injectors and decrease your generators performance. These fuel deposits can also produce backpressure, erode the surface of your engine, and reduce the efficiency of the overall system. These side effects will shorten equipment life significantly, leading to an increase in repair costs.

Wet stacking can also affect your engine oil quality. Because your engine is running at sub optimal temperatures, the pistons don’t meet the cylinder like they should. This can cause unburned fuel to leak into the oil pan, diluting the oil. This decreases your oil’s ability to protect your engine and causes increased wear.

Wet stacking leads to increased pollution, and most cities restrict smoke emissions caused by wet stacking. This can lead to major fines if discovered by the EPA.

Power production is reduced as well, even before your engine shows any external signs of damage. An engine that experiences wet stacking requires more maintenance at shorter intervals than engines that do not. Overall, wet stacking is a side effect you want to avoid if you are trying to get the most longevity and efficiency from you diesel generator. Our generator technicians at Energy Management Corporation are experts at generator maintenance and can help with any generator problems you may come across, including wet stacking.

Got More Generator Questions? We Can Help!

Call 800-595-5315 Or Connect With Our Expert Technicians Here:

Other Articles

- Critical Spare Planning

- Where Do I Start On My Generator Installation?

- How can Las Vegas heat lead to generator failures?

Lead Generator Technician

Graduated from Idaho State University with a degree in Heavy Duty Diesel and Onsite Power Generation. Damien is a master tinkerer and has been working on anything with a motor since he was about six years old. Besides being a generator fanatic, Damien is also an avid snowmobiler and aspiring world traveler.