Anti-Clogging – Deraggers vs. VFDs

Blockages are a problem encountered by wastewater systems all over the world. As more trash enters the wastewater system, it leads to clogs that must be dealt with. The National Association of Clean Water Agencies (NACWA) reported on studies that showed the rise of flushable wipes poses a massive problem to wastewater systems.

These wipes don’t break down enough to prevent clogs. These wipes, along with other trash and debris, can lead to overflows, runoff, and other disastrous and expensive issues. Just these wipes alone are estimated by the NACWA to add $441 million per year in operating costs at clean water utilities.

This problem has often been dealt with through shredders, grinders, and macerators, meant to tear these blockages apart and keep water moving. This is often not enough. This is where many wastewater facilities turn to deragging technologies, also called anti-ragging or anti-clogging. These technologies can help to keep systems running smoothly.

Deragging Devices

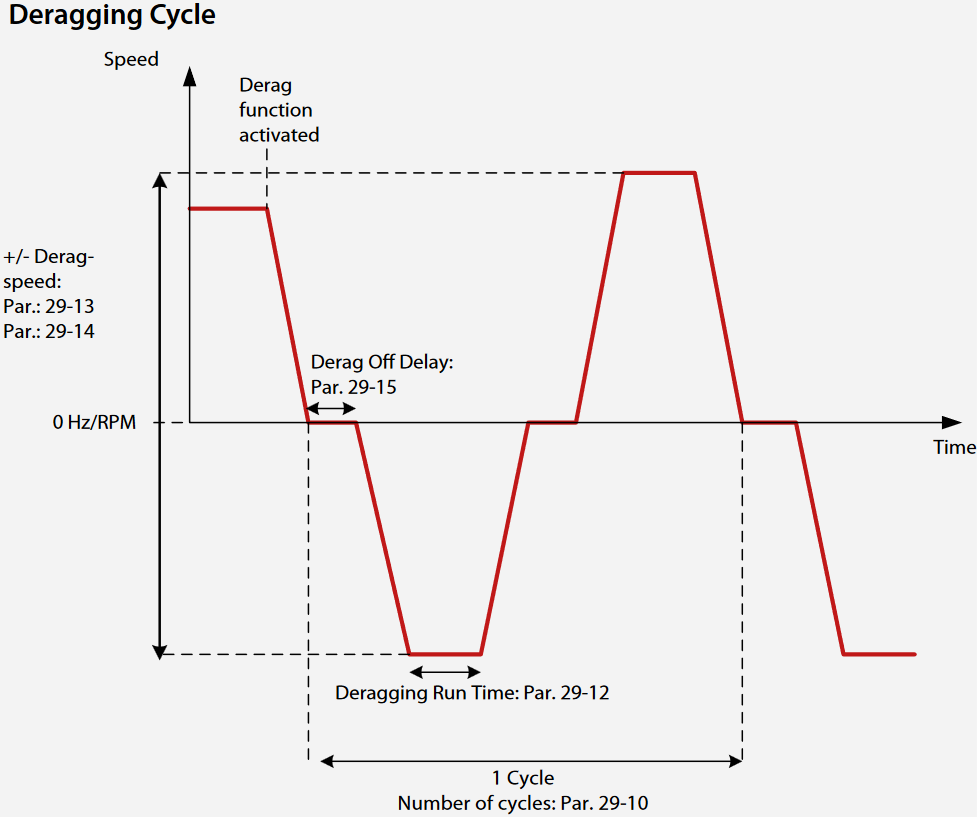

A typical deragger functions by using the pumps and waterflow itself to help break up blockages. The deragger reverses the pump and water flow. This helps to agitate the water and break up and clogs that may have formed. You can often program the length of time you want it to reverse, typically adjusted based on the amount and severity of blockages your system encounters.

Most deraggers have several possible methods of functioning. The first is that they are set to reverse at set intervals. This interval is often set based on the typical experience of the installer and later adjusted based on how well it is working to clear the system.

Many deraggers also have the capability to add digital monitors. These monitors allow you to monitor when a blockage may be forming and help to engage additional deragging cycles. They can send information back to a control system, trigger alarms, and be manually engaged.

Anti-clogging with VFDs

Over the past several years, variable frequency drives, or VFDs, with advanced deragging technology and capabilities have become more common. Many wastewater systems are already utilizing VFDs in their pumping systems, but have not explored using a VFD as the deragger.

While not every line of VFDs has the capability, it is becoming much more common. VFD anti-clogging works very similarly to a deragger device. You can set time intervals for deragging, with variable time lengths of reversing and agitation.

Deragger VFDs also have the digital monitors that are available in deragger devices, but they’re already built in. When commissioning the VFD, you run the pump and motor at various speeds to build a curve of the normal amperage at those speeds. The VFD uses that to learn what typical, unblocked usage looks like.

Based on normal operation, whenever the VFD senses underload or overload conditions, it engages a deragging cycle to agitate and clear the blockage. You also can integrate PID controls to engage these cycles.

Most VFDs also come with many options for BMS and SCADA connections and controls, meaning you can often manually engage anti-clogging cycles from a control room, or even at the VFD itself.

Which Do We Recommend?

Deraggers a great way to reduce the number of clogs that your wastewater system sees. They work in well systems, but the recent advances in VFD technology make them a much more attractive option to help improve your water system. Not only do you gain the same functionality and monitoring as a deragger, you also gain additional benefits outside of anti-clogging.

VFDs save power consumption by reducing the electricity needed to run your motors and pumps. They allow your motors to start without the inrush that damages the motor, and some can help with soft pipe fill, or pre-charging. They can also help to avoid mechanical stress on your system by reducing the need to use check valves, as well as reducing water hammer and vibration.

Case Study – Retrofitting a VFD with Deragging

A wastewater system was performing upgrades to a pump station. This pump station had multiple pumping systems, with two VFDs needed to be replaced. As the team looked at upgrading VFDs, they knew that clogging was an issue that would need to be addressed.

The pump stations within this system had always used deragging devices in the past to help clear any blockages. While replacing VFDs, they initially planned to install new deraggers.

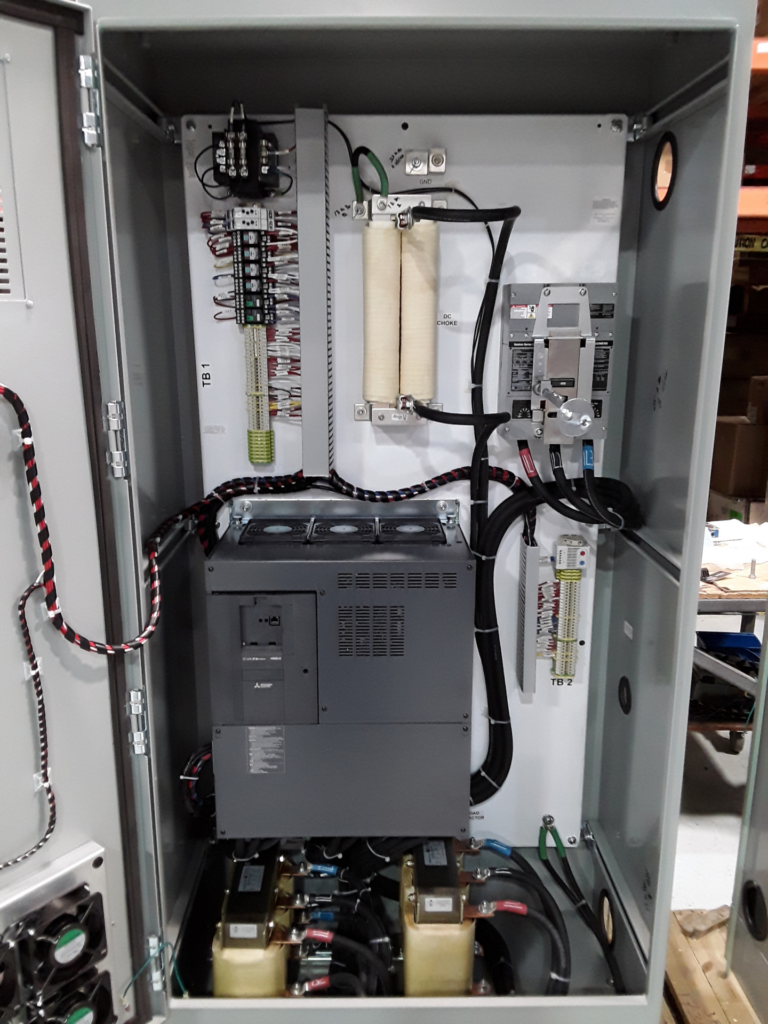

Our engineering team knew that this was the perfect opportunity to look at VFDs with built-in anti-clogging capabilities. The requirements for the system would already need full VFD control panels, so we went through a design phase to help implement the best solutions.

The wastewater team specified that they wanted redundancy and reliability. Bypass and harmonic mitigation options were added to the system, and the communications were coordinated so that the entire system could be controlled remotely. They also wanted the ability to add an emergency stop and several manual controls to engage deragging cycles whenever the team felt it was necessary.

After exploring the capabilities of the built-in deragging, the wastewater team decided that a VFD with this functionality was an acceptable technology to meet the specification. Our team moved forward with the engineering, production, and delivery of the panels.

Our technicians helped to remove the old VFDs, install the new ones, and commission the entire system. This process included setting up the curves to detect overload conditions, designating regular intervals, and specifying when too many deragging cycles would send an alarm to the control room for further inspection.

After commissioning the new VFDs, they went through months of observation and testing. The VFD deragging capabilities performed exactly as the wastewater team needed. They were able to simplify their system during the upgrade, while keeping all the functionality they needed to continue delivering water to their community.

Let Us Help You

When you start to look at your wastewater system as a whole, you want to reduce the complexity while increasing efficiency and reliability. While deraggers help to reduce clogs, VFDs perform the same role with more options included and increased advantages, all in one device.

Most wastewater systems are already using VFDs. Being able to include this functionality with fewer devices is a benefit that we’ve seen help systems to get the best system with the least overall headache.

Our teams of engineers and technicians have decades of experience working on water systems. We’ve installed hundreds of VFDs and have worked with deragging systems on many projects. We can handle installation, commissioning, and all the necessary programming and coordination.

If your water system needs anti-clogging help, reach out to us and we’ll help you find the right products, get them installed, and program each one to the exact needs of your facility.

Marketing Manager

Tyler is a marketing manager focusing on VFD, motor, and generator applications. In the past he’s worked in sales for these same products. He is a proud graduate of Utah State University and enjoys spending time with family and friends.